|

|

|

|

POLARIS PERFORMANCE MAIN BEARINGS

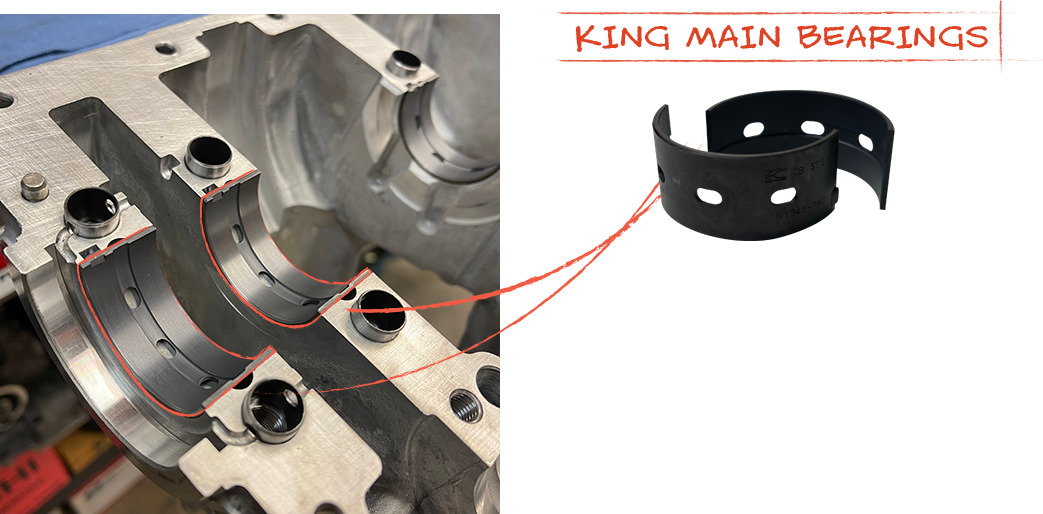

New King main bearings for the Polaris RZR platform are now available. The BC 4340 billet XP crankshafts are an improvement to the rod bearing failures but they aren’t the cure for the oiling issues. These exclusive BC/TPR mains from King Bearing however do provide the proper oiling from the mains to the rods with some qualified machining. King XP line bearings are a hardened coated race bearing vs the OE soft Babbitt bearing. To thoroughly “bulletproof” the case, we designed an oversize O.D. (1.750”) main bearing in 3 grades (Standard, +.0003” and -.0003”) that are designed to accommodate an over bored case. Lineboring assures that the case halve main journals are true, round and aligned. TPR also offers a shuffle pinning feature using a dowel system that keeps the case halves properly aligned during the torque sequence, allowing the use of the ARP main studs. Great for turbo, endurance or anyone who’s experienced the agony of a burned up Mag side #2 rod. These oversize (1.750" O.D.) bearings only work with linebored cases, where the main bearing housing bores have been machined to a larger diameter to true up the Polaris cases that are lacking in proper tolerances. These cases can be as much as .006" out of round causing oil to hemorrhage out the lower case half, losing oil pressure to the rods. King’s unique combination of design, metallurgy and engineering deliver what experienced builder’s expect from a high performance Trimetal engine bearing. Designed to withstand higher RPM and extreme conditions, King Race Series Engine Bearings, along with the linebored and shuffle pinned case, has virtually solved the oiling issues inherent with the Polaris RZR engines. Contact BC for qualified machine shops to handle the lineboring and pinning.

|

|

|

|

Part # |

|

Description # |

|

Sizing |

|

Buy Now |

|

Status |

|

|

| BC4900 |

BEARINGS - King Race Series, Coated Oversize Main Bearings - Requires linebored case to install |

Standard |

|

In-Stock |

|

| BC4900-O |

BEARINGS - King Race Series, Coated Oversize Main Bearings - Requires linebored case to install |

+.0003" |

|

In-Stock |

|

| BC4900-U |

BEARINGS - King Race Series, Coated Oversize Main Bearings - Requires linebored case to install |

-.0003" |

|

In-Stock |

|

|

|

|

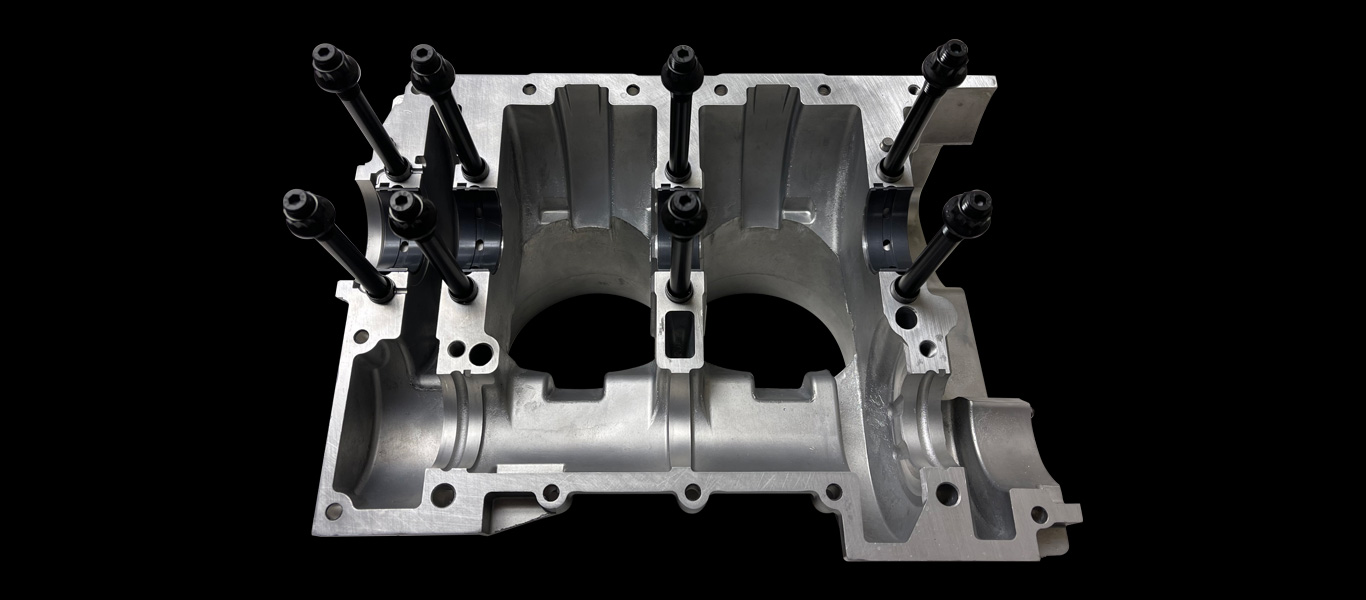

POLARIS RZR HIGH PERFORMANCE CRANKCASE

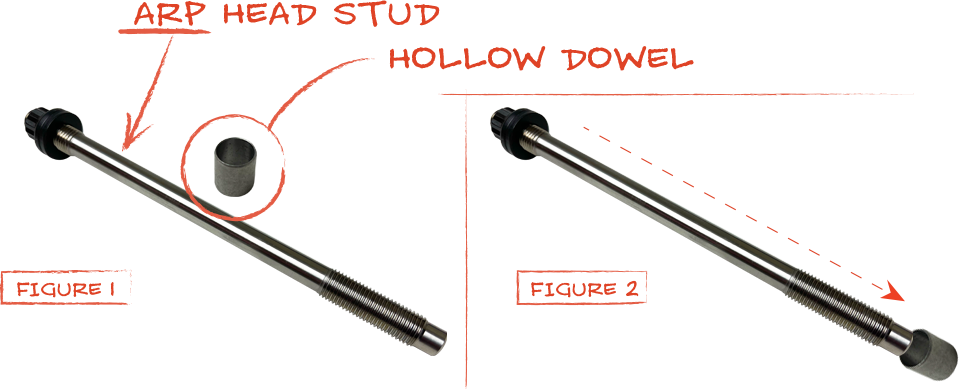

BC/TPR, in conjunction with King Bearings, has developed the most bulletproof crankcase currently available on the market. RZR cases have notoriously out of round main journals (up to .006") which allows oil to hemorrhage out of the lower case halve. This is the root cause of burning up the #2 Mag side rod as well as oiling up to the cams and buckets. The solution is to linebore the case halves to an oversize 1.750" O.D. to true up the main journals and installing the oversize King race series main bearings. Then we shuffle pin the case using hollow dowels inserted into each main stud orifice. This keeps the case halves from shifting when torquing the ARP main studs. Keep reading below for complete details on the process. |

|

|

|

Part # |

|

Description # |

|

Buy Kit |

|

Status |

|

|

| BC4910 |

RZR HIGH PERFORMANCE CRANKCASE - Features Linebored and Shuffle Pinned Case, King Main Bearings, ARP Main Studs - Custom Supplies Crankcase |

|

In-Stock |

|

|

|

really.... thats it?

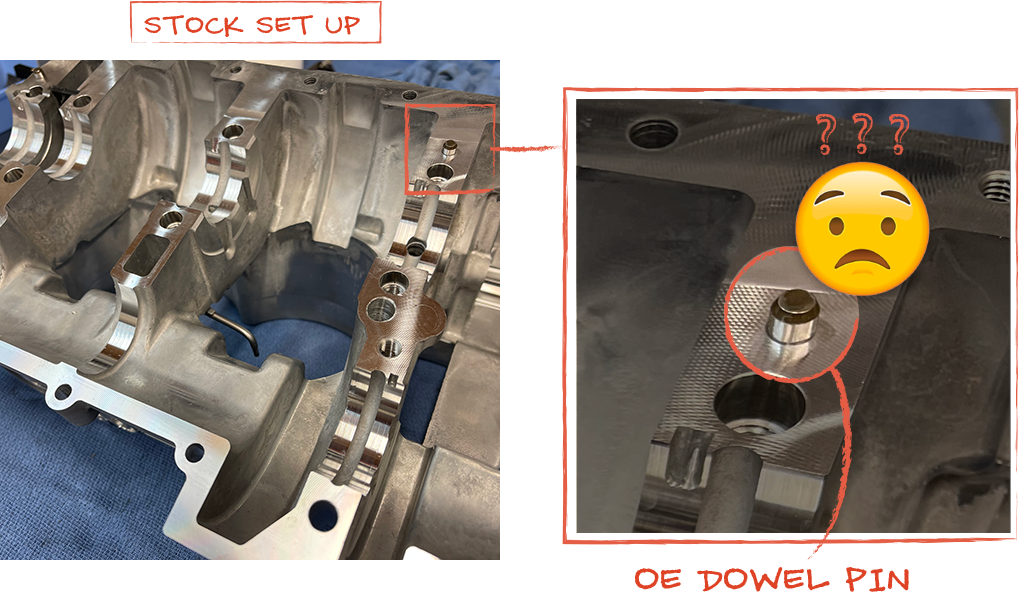

The Polaris OE factory crankcase only incorporates two small dowel pins to align the entire case halves. This is sufficient for factory main studs, where the torque specs are 21 ft lbs. However if you want to utilize the ARP2000 main studs, with a torque spec of 60 ft lbs, these two pins cannot accommodate the load created by the increased torque, allowing the two case halves to shift by as much as .010". This allows oil to hemorrhage out the lower half, losing oil pressure up to the rods and even the cylinder head, cams and lifter buckets.

|

|

|

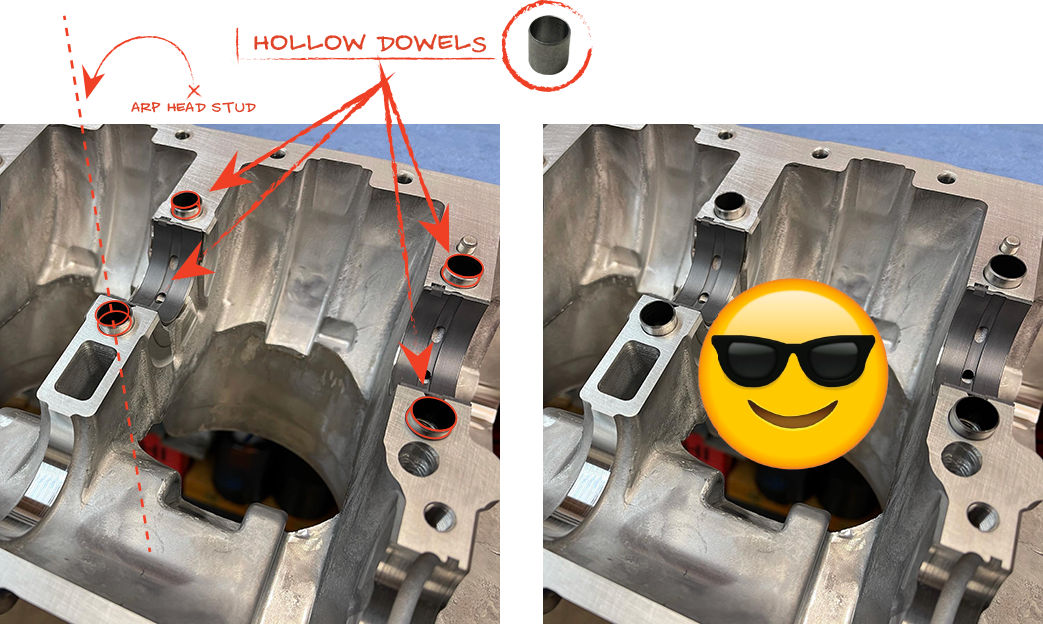

Where the magic happens.

BC/TPR has solved the above issue with the case halves shifting by "shuffle pinning" the case halves. This procedure involves CNC milling each of the stud holes to accommodate the dowels, then installing eight hollow alignment dowels into the case halve, one on each side of every main journal. By "pinning" the case halves, there's no shifting or alignment issues, regardless of how many times you retorque the case. With this system, the main journals are now with .0002" tolerance...practically perfect!

|

|

|

LINEBORING

Back in 2019, we approached King Bearing to make stock replacement Race Series bearings for the RZR, then Covid hit and stalled the project out. Luckily this gave us time to get more Polaris cases into the shop, both new ones and used ones, and what we found was that regardless if new or used, the stock Polaris main bores were not true, meaning they were out of round by as much as .006". Putting a race bearing into an out of round case would've just created the same problem (burning up the #2 Mag side rod), so we shelved the stock replacement design and went with a 1.750" OD oversize bearing. To accommodate that oversize bearing and true up the main bores, we linebore the two case halves while together to create a perfect circle in every main bore. Now when we install the King XP hardened, coated race bearing, we're down to .0002" and have tested this setup in over 500whp drag cars, endurance desert racing and short course applications with fantastic results!

|

|

|

ARP MAIN STUDS

Up until now, due to the fact that there's only two small dowel pins for case alignment, there was no way to incorporate the ARP main studs into the RZR builds because the case halves would shift when torquing these higher grade studs to the proper torque specs. By installing eight hollow alignment dowels (shuffle pinning) into the each main stud orifice, each main journal remains true to .0002".

|

|

|

|

619.749.9018 ph

619.749.9128 fx

|

| Some products listed are not legal for sale or use on emission controlled motor vehicles, RPM ranges vary on application.Warranty Information Copyright © Brian Crower Inc. All rights reserved.. |

|

|

|

WARNING: This product can expose you to chemicals,

including Chromium (hexavalent compounds), lead and lead

compounds, which are known to the State of California to

cause cancer, birth defects or other reproductive harm. For

more information, visit www.p65warnings.ca.gov |

|

|

|

|

|